Main product series

Zhongli was founded in 1997 with a registered capital of 100 million yuan. It is a high-tech enterprise specializing in the production of various alloy forgings and equipment structural components.

Shanxi Zhongli heavy precision forging Co.,LTD.

(Shanxi Zhongli Flange Co.,LTD.)

Shanxi Zhongli Heavy Forging Co., Ltd. (Shanxi Zhongli Falan Co., Ltd.) is located in Dingxiang County, Xinzhou City, Shanxi Province, 10 kilometers from Wutai Mountain Airport. Established in 1997, with a registered capital of 100 million yuan, it is a high-tech enterprise specializing in the production of various alloy forgings and equipment structural parts. The company covers an area of 125 mu, with 205 employees and total assets of 420 million yuan. It has the capability of integrated operation from design, blanking, forging, ring rolling, spinning, welding, riveting, heat treatment, machining, physical and chemical testing, mechanical performance testing, non-destructive testing, assembly, packaging, and shipment.

Establish

Registered capital

Cover an area

is a high-tech enterprise specializing in the production of various alloy forgings and equipment structural parts.

The company has complete qualifications and possesses four military industry certificates, ISO9001:2008 quality system certificate...

Established in 1997 with a registered capital of 100 million yuan, it is a high-tech enterprise specializing in the production of various alloy forgings and equipment structural parts.

Respect, cultivate, and affirm every employee, provide a platform to actively guide employees to participate in the innovative development of the enterprise

Shanxi Zhongfa Lawran Co., Ltd.

Unity and Strength, Integrity and Trust

Shanxi Zhongli Heavy Forging Co., Ltd. (Shanxi Zhongli Falan Co., Ltd.) is located in Dingxiang County, Xinzhou City, Shanxi Province, 10 kilometers from Wutai Mountain Airport. Established in 1997, with a registered capital of 100 million yuan, it is a high-tech enterprise specializing in the production of various alloy forgings and equipment structural parts. The company covers an area of 125 mu, with 205 employees and total assets of 420 million yuan. It has the capability of integrated operation from design, blanking, forging, ring rolling, spinning, welding, riveting, heat treatment, machining, physical and chemical testing, mechanical performance testing, non-destructive testing, assembly, packaging, and shipment.

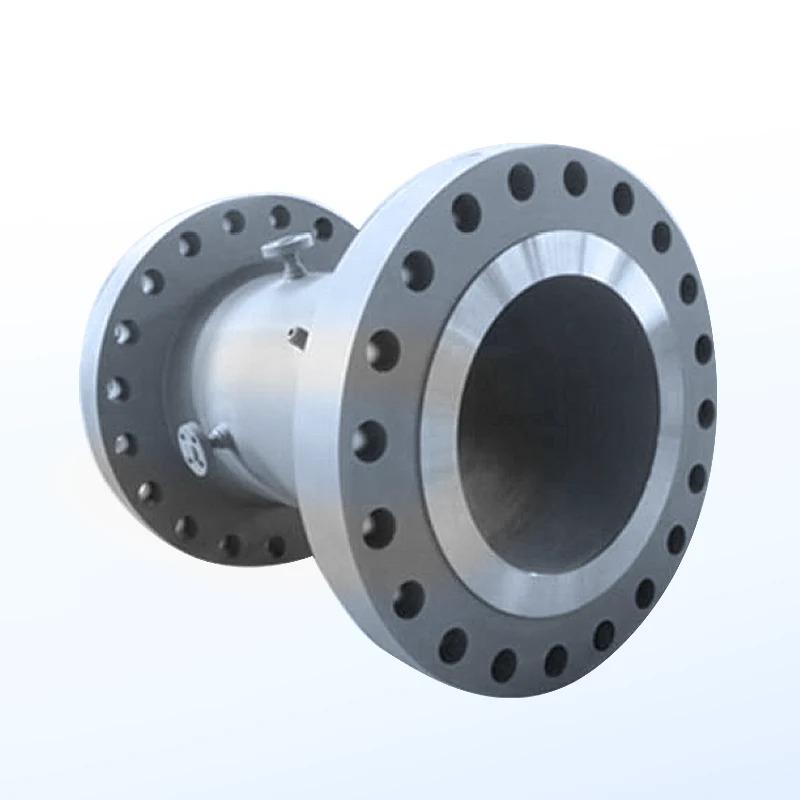

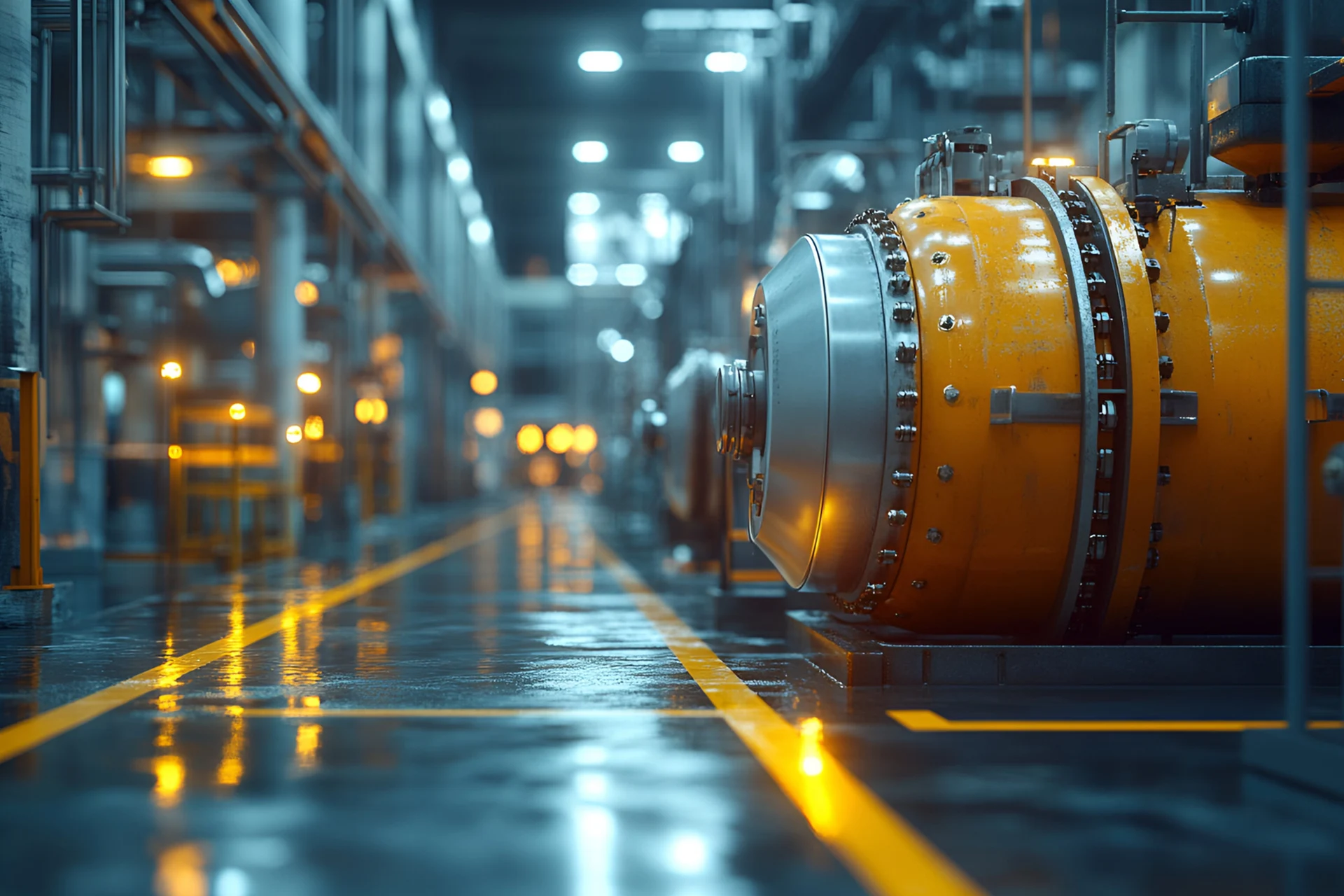

Products are mainly used in aviation, aerospace, weaponry, shipbuilding, steam turbines, petroleum refining, coal chemical industry, metallurgy, nuclear power, pressure vessels and other fields.

The company's annual production capacity reaches 50,000 tons. It has the capability to forge large forgings with a diameter of 8 meters, a single weight of 50 tons, and a radial height of 1.3 meters, and spin-pressed metal thin-walled shells with a wall thickness >2mm, a diameter of 2 meters, and a length of 4 meters. It possesses advanced equipment such as 8000-ton and 1600-ton hydraulic presses, CNC 8-meter high-diameter ring rolling machines, rapid quenching production lines, bogie heat treatment furnaces, CNC machining centers, and a complete set of physical and chemical testing equipment. It can produce large forgings within 50 tons, including ring, cylinder, shaft, disc, ball, and various other shapes.

Establish

Registered capital

Cover an area

is a high-tech enterprise specializing in the production of various alloy forgings and equipment structural parts.

The company has complete qualifications and possesses four military industry certificates, ISO9001:2008 quality system certificate...

Established in 1997 with a registered capital of 100 million yuan, it is a high-tech enterprise specializing in the production of various alloy forgings and equipment structural parts.

Respect, cultivate, and affirm every employee, provide a platform to actively guide employees to participate in the innovative development of the enterprise

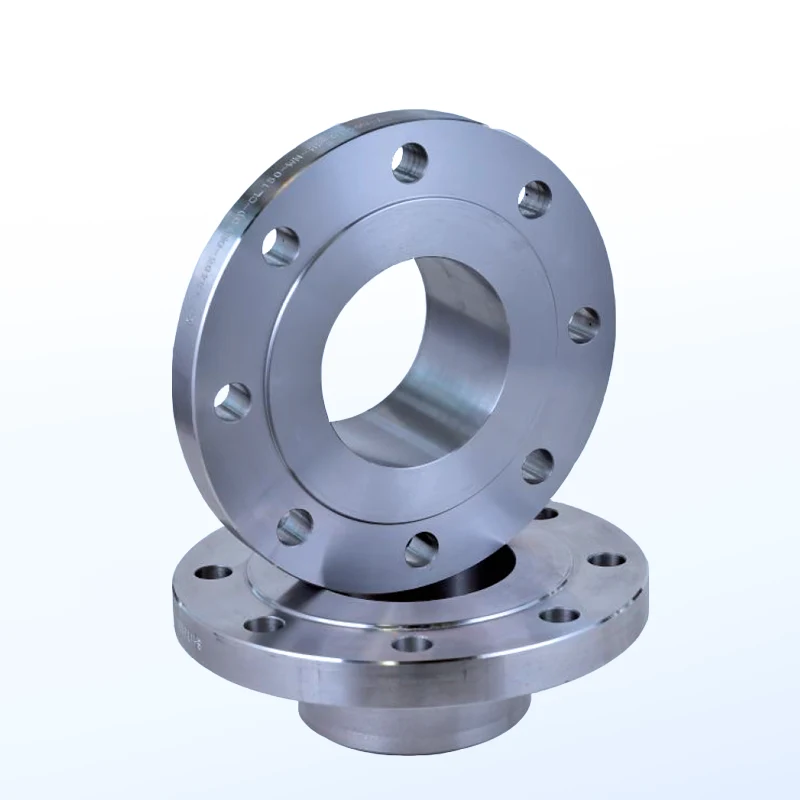

Main Products

The company's annual production capacity reaches 50,000 tons. It has the capability to forge large forgings with a diameter of 8 meters, a single weight of 50 tons, and a radial height of 1.3 meters, and spin-pressed metal thin-walled shells with a wall thickness >2mm, a diameter of 2 meters, and a length of 4 meters.

Application Cases

Products are mainly used in aviation, aerospace, weaponry, shipbuilding, steam turbines, petroleum refining, coal chemical industry, metallurgy, nuclear power, pressure vessels and other fields.

Petrochemical

Oil and gas pipelines

Pressure vessels

Engineering machinery

Wind power generation

Shipbuilding

Aerospace

Power plants

Qualifications and Honors

The company has complete qualifications, including four military industry certificates, ISO9001:2008 quality system certificate, China special equipment manufacturing license, PetroChina material supplier network certificate, Sinopec material resource market member certificate, etc.

News

The company is committed to the research, design and development of material handling equipment, providing you with comprehensive material solutions

What are the reasons for flange rusting and failure of rust prevention?

The main reason for rust on flanges is the chemical reaction that occurs when their material comes into contact with oxygen and water in the environment.

2025-08-19

5 Key Factors Affecting Stainless Steel Flange Prices

As an indispensable component for connecting piping systems, the price fluctuation of stainless steel flanges is closely related to various factors, reflecting the complexity and dynamics of the market.

2025-08-15

The difference between stainless steel slip-on flanges and butt-welding flanges

Connection method: Stainless steel flat welding flanges are connected by welding the flange to the pipe, usually by butt welding. Butt welding flanges are connected by aligning the holes drilled on the T-shaped profile with the pipe and using bolts to achieve the connection between the flange and the pipe.

2025-08-11

Regular maintenance: Regularly maintaining stainless steel flat welding flanges is an important measure to extend their service life. Through maintenance work such as cleaning, lubrication, and inspection, problems can be detected and dealt with in a timely manner, avoiding further damage.

2025-08-19

Partners

Brand of Trust

The company has strong technical strength. In its more than 20 years of development, its products have been widely used in national large-scale projects and major models. The anchoring flange designed and developed by the company has been awarded three patents by the State Intellectual Property Office: "Appearance Design", "Material Invention", and "Utility Model".