Patented Products

Anchor Flange, Patented Product, West-East Gas Pipeline, First Supplier

In 2001, Zhongli Company successfully designed and developed anchor flanges suitable for large-scale oil and gas pipelines, and obtained three patents. For the first time, it replaced imports and was installed on the main pipelines such as the West-East Gas Pipeline Project Phase I, II, the Shaanxi-Beijing III Line, the Southwest Interconnection Line, the Sichuan-East Gas Pipeline, and the Mohe-Daqing Line. It has been operating well and has been well received by users. It was awarded the title of "Excellent Supplier" by PetroChina.

Scientific and Technological Research and Development

Taking "Technological Innovation" as the Development Direction

The company has always taken "technological innovation" as its development direction. For many years, it has cooperated with many scientific research institutions to jointly develop new products and new technologies. Among them, the "hollow casting blank - rolling - spinning integrated process" has been widely used in the aerospace field. On December 27, 2019, it participated in the formulation of the standards QDU380-2019 "Technical Conditions for 2A14 Aluminum Alloy Hollow Casting Blanks", QDU302-2019 "Technical Conditions for 2A14 Aluminum Alloy Conical Rolling Forgings", and QDU390-2019 "Technical Conditions for 2A14 Aluminum Alloy Conical Spinning Forgings" by the China Academy of Launch Vehicle Technology.

Key Technologies

Zhongli dares to break through and overcome difficulties in materials, processes, and information technology. Three core technologies lead the industry.

Independent R&D of New Materials CF62 Improved Type

It greatly improves the welding performance, reduces and even eliminates the generation of five major cracks during welding; the steel has high purity, fine and uniform grains, reaching 7-10 levels, good comprehensive mechanical properties, especially the -40℃ impact value can actually reach ≥ 280J, and the low-temperature long-term use toughness safety factor is very large, and can be used for a long time.

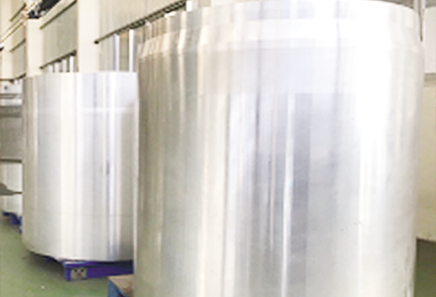

Integrated Forming Technology for Large and Complex Light Alloy Structural Parts

New technologies such as high-strength aluminum alloy large and complex component primary and secondary control deformation, multi-directional loading rotary extrusion, and radial reverse composite extrusion have been invented to achieve integrated forming. It is a domestic innovative technology with low cost, high efficiency, short process, and high strength.

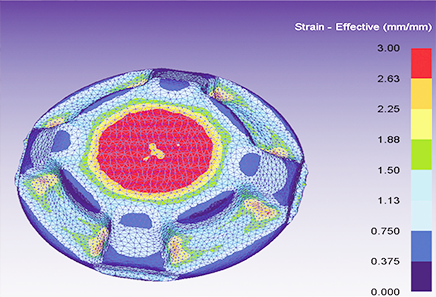

Full-Process Production Data Simulation Technology

It can perform numerical simulation on aspects such as the temperature field, stress field, metal flow filling during the forming process, the stress borne by the mold, and the defects generated during forming, optimize the process design, and shorten the product R&D cycle.