Product Categories

Contact Us

Address: Dingxiang, Xinzhou, Shanxi, China

Mobile:+86-18535089110

Email:zhongliflange@163.com

In extreme operating conditions involving high pressure, high temperature, or severe corrosion, the longitudinal welds of traditional pressure vessel cylinders—formed by rolling and welding steel plates—have always been the weakest link in the reliability chain. Our cylindrical forgings, produced through the “direct forging from solid ingots” process, fundamentally eliminate this longitudinal weld.

In heavy-duty gearboxes, hydroelectric generator sets, or marine propulsion systems, the failure of a single drive shaft often means production line shutdowns and massive losses. Therefore, we believe the value of an exceptional shaft forging lies not only in meeting dimensional and strength specifications but also in its predictable and stable performance throughout its entire design life.

At Zhongfa Flange, we view every ring forging as a structural component bearing critical stresses. It could be a bearing ring on a wind turbine main shaft, a wheel ring on a large rotary kiln, or a compression ring on a chemical vessel. Its performance directly determines the operational precision, load-bearing capacity, and service life of the end equipment.

Unlike simply cut rings, we employ integral forging combined with radial-axial ring rolling. This ensures continuous circumferential distribution of metal fibers, eliminating weld seams and weakened zones. Consequently, it delivers unmatched reliability in fatigue resistance, fracture toughness, and dimensional stability—far surpassing sheet rolling or segmental welding methods.

In heavy equipment manufacturing, when a steel plate exceeds 100mm in thickness, it transitions from being called “plate” to a “pancake” requiring specialized forging. Traditional thick plates suffer from inherent flaws like loose core structure and anisotropy. Our disc-shaped forgings overcome this through repeated upsetting and drawing in an 8,000-ton press. Like kneading dough, this process reshapes the metal from its core, achieving crystal structures and mechanical properties as dense in thickness as at the surface.

A compressor short section is a short length of pipe or fitting used in piping systems to connect a compressor to other equipment. This design plays an important role in many industrial applications, especially in refrigeration, air conditioning, and gas transmission systems. This article will analyze compressor short sections from the aspects of concept, characteristics, application scenarios, and selection.

A boss is a structure or industrial component with a unique shape, widely used in various engineering, construction, and mechanical fields.

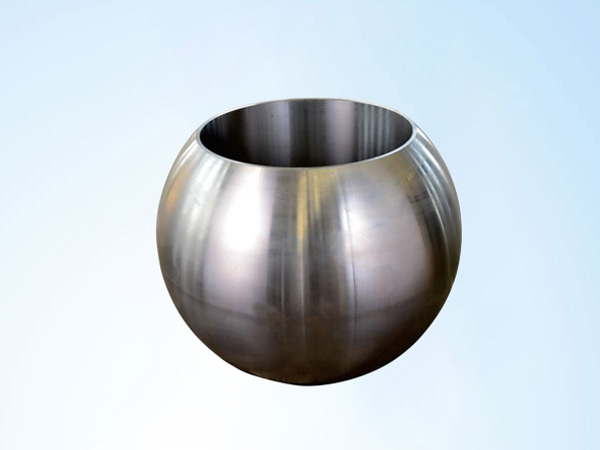

Ball valves mainly consist of a valve body, ball, valve seat, and driving device.