Product Categories

Contact Us

Address: Dingxiang, Xinzhou, Shanxi, China

Mobile:+86-18535089110

Email:zhongliflange@163.com

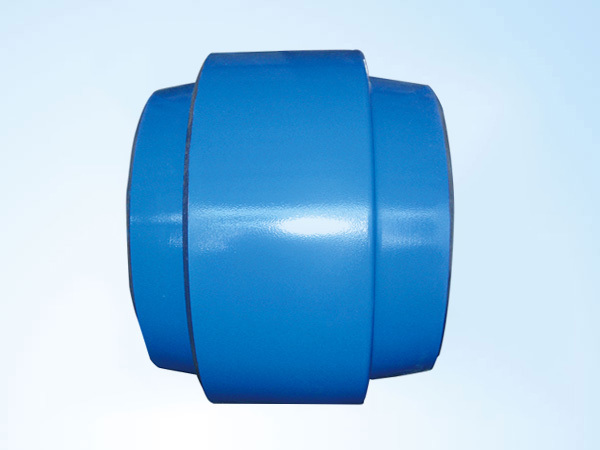

Anchoring Flange

- Product Description

-

I. Overview of Anchor Flanges

Anchor flanges are connecting devices widely used in the petroleum, chemical, and power industries. Their main function is to establish a firm connection between pipes or equipment, ensuring the safe transmission of media. Anchor flanges typically consist of a flange, bolts, gaskets, and fasteners, and are characterized by convenient connection, high strength, and good sealing performance.

II. Importance of Anchor Flanges

The length, material, and pressure rating of anchor flanges directly affect their connection effectiveness and safety. Length, as one of the key parameters, is related to the flange's stability and sealing performance. Therefore, the correct selection and application of anchor flanges are crucial for ensuring the safe operation of pipeline systems.

III. Anchor Flange Length Analysis

The length of an anchor flange mainly includes the connection length, gasket thickness, and additional length. A suitable length not only ensures the stability of the connection but also ensures good sealing performance. In practical applications, the selection of anchor flange length should be based on the actual needs and conditions of the pipeline system, including pipe diameter, working pressure, and media properties.

IV. Applications of Anchor Flanges

In the petroleum, chemical, and power industries, anchor flanges are widely used in the connection of various pipeline systems. During selection and application, the type, material, pressure rating, and length of the flange should be fully considered to ensure the reliability and safety of the connection. In addition, during installation, relevant standards and specifications must be followed to ensure the correct installation and use of the flange.

V. Precautions

1. When selecting anchor flanges, the selection should be based on actual needs and conditions to ensure that the flange parameters meet the requirements of the pipeline system.

2. During use, the connection status and sealing performance of the flange should be checked regularly to promptly identify and address potential problems.

3. During installation, relevant installation specifications must be followed to ensure correct flange installation.

4. In special environments, such as high temperature, high pressure, and corrosive media, suitable materials and types should be selected to ensure the safe use of the flange.

In summary, anchor flanges, as important connecting devices, are widely used in the petroleum, chemical, and power industries. The correct selection and application of anchor flanges are of great significance for ensuring the safe operation of pipeline systems.

Keywords:

Zhongli

Flange

Get a Quote

Related Products